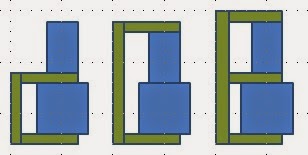

Some photos!! First, the plates between the wishbone tubes. This was cut from 5mm plate with a standard jigsaw and some Bosch blades. Plenty of cutting fluid, and several hours later, I had this;

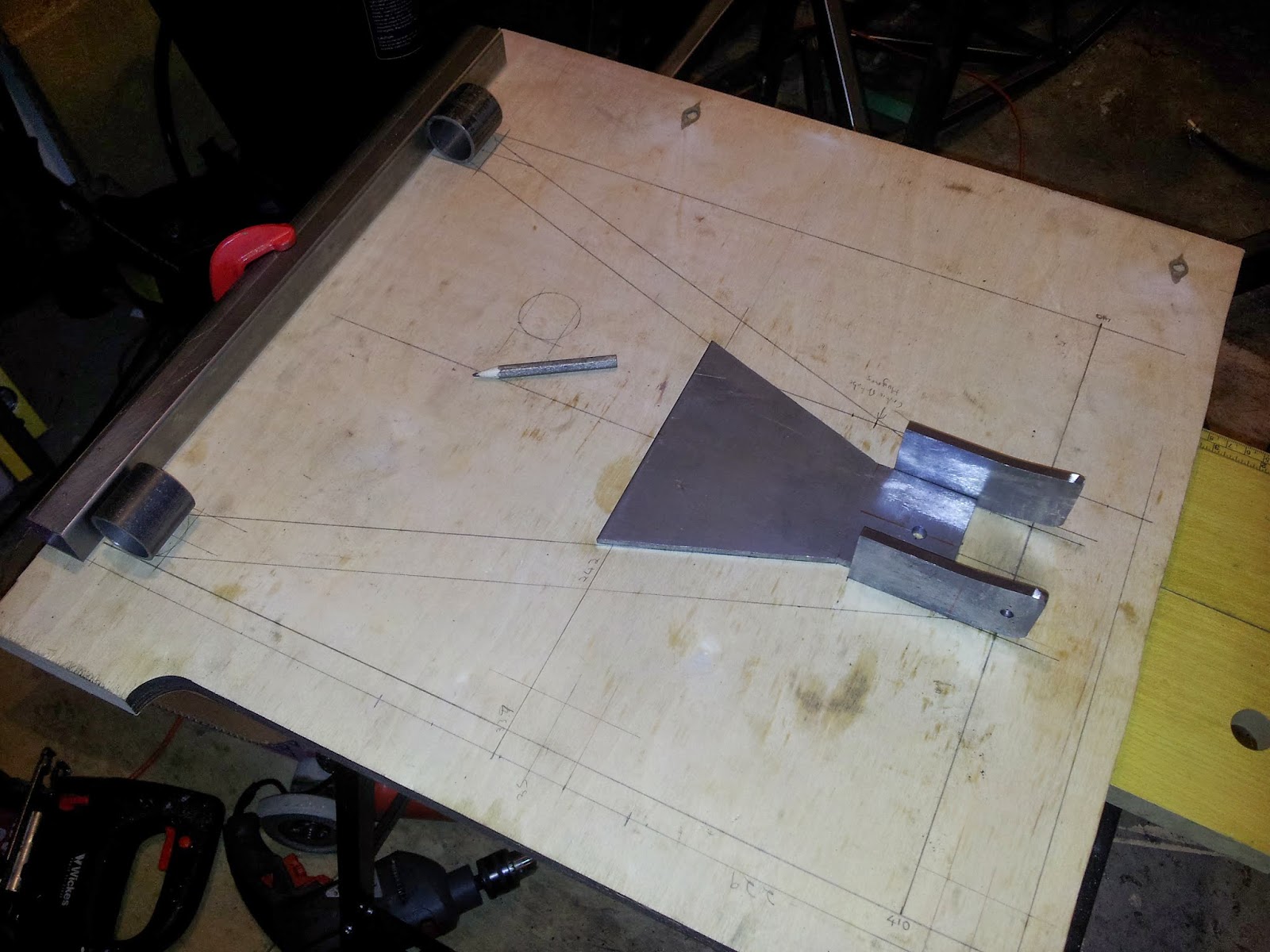

Next were the tubes themselves, just cut to length and then manually profiled to the bush tubes;

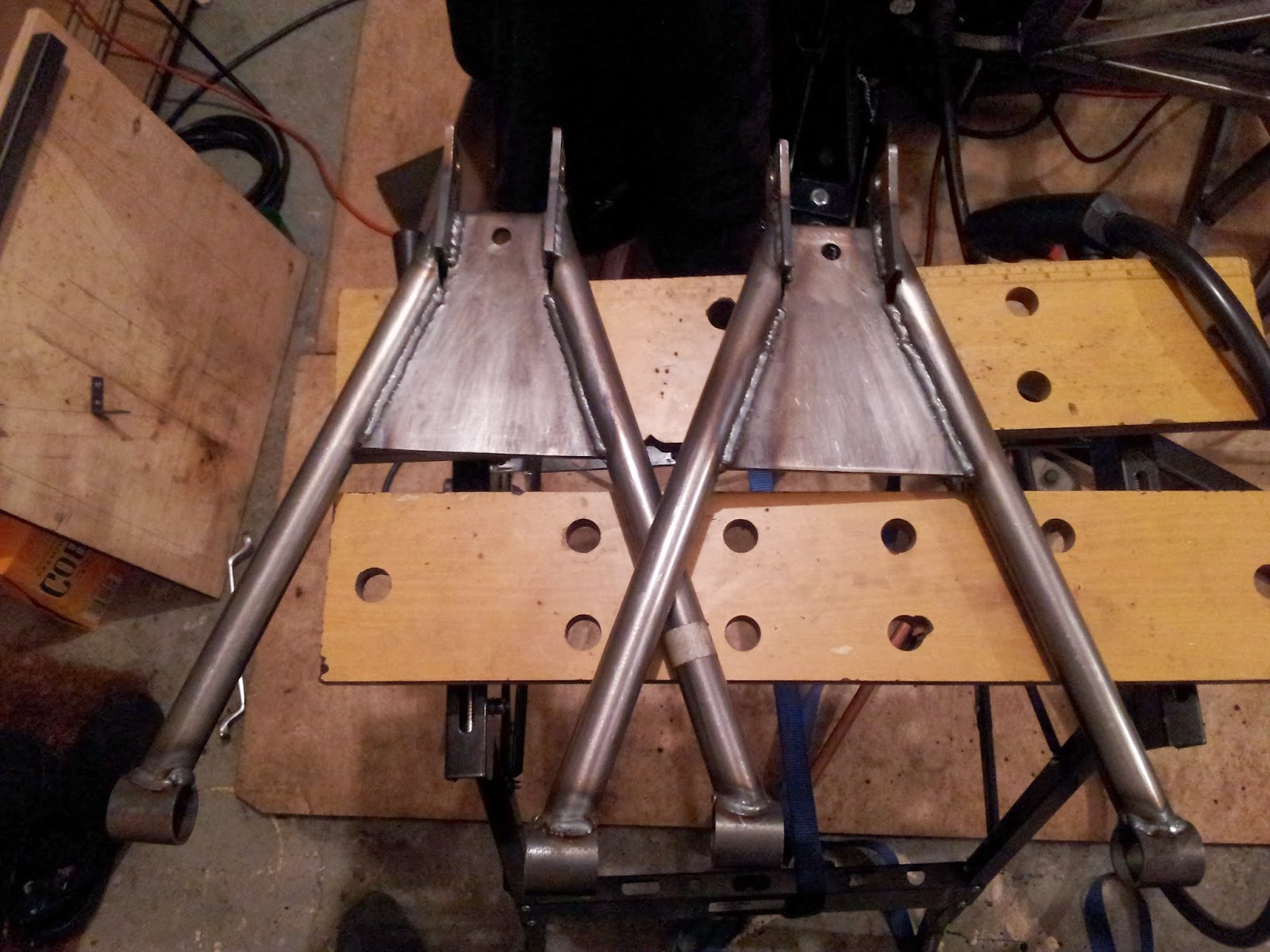

As the lower wishbones aren't handed, I did them all using this jig. That way I knew they would all be identically right (or identically wrong!). The plates I had cut for other parts of the suspension came in very useful as spacers, I kind of ignored the spacers suggested as it didn't leave all the seams in the centre. And when I was welding I wanted to make sure I was welding on welds.

Then came the bottom cut. First I tried marking it with a laser beam;

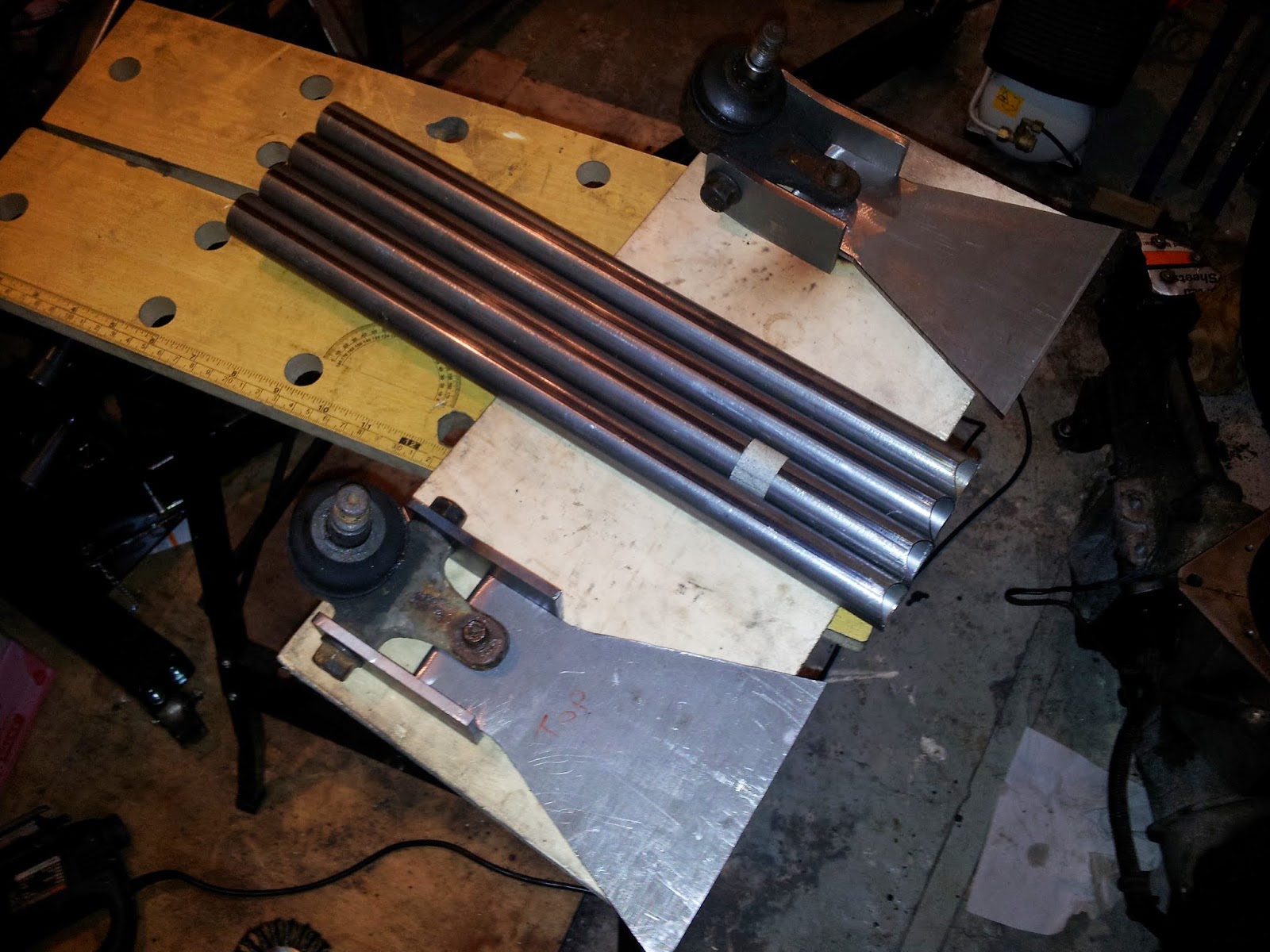

But I couldn't get it to line up perfectly, so I went for an old fashioned handsaw jig. Again, lots of hours and lots of cutting fluid later, I had all pipes cut, and a full set of parts;

A first fit showed a bit of trimming needed;

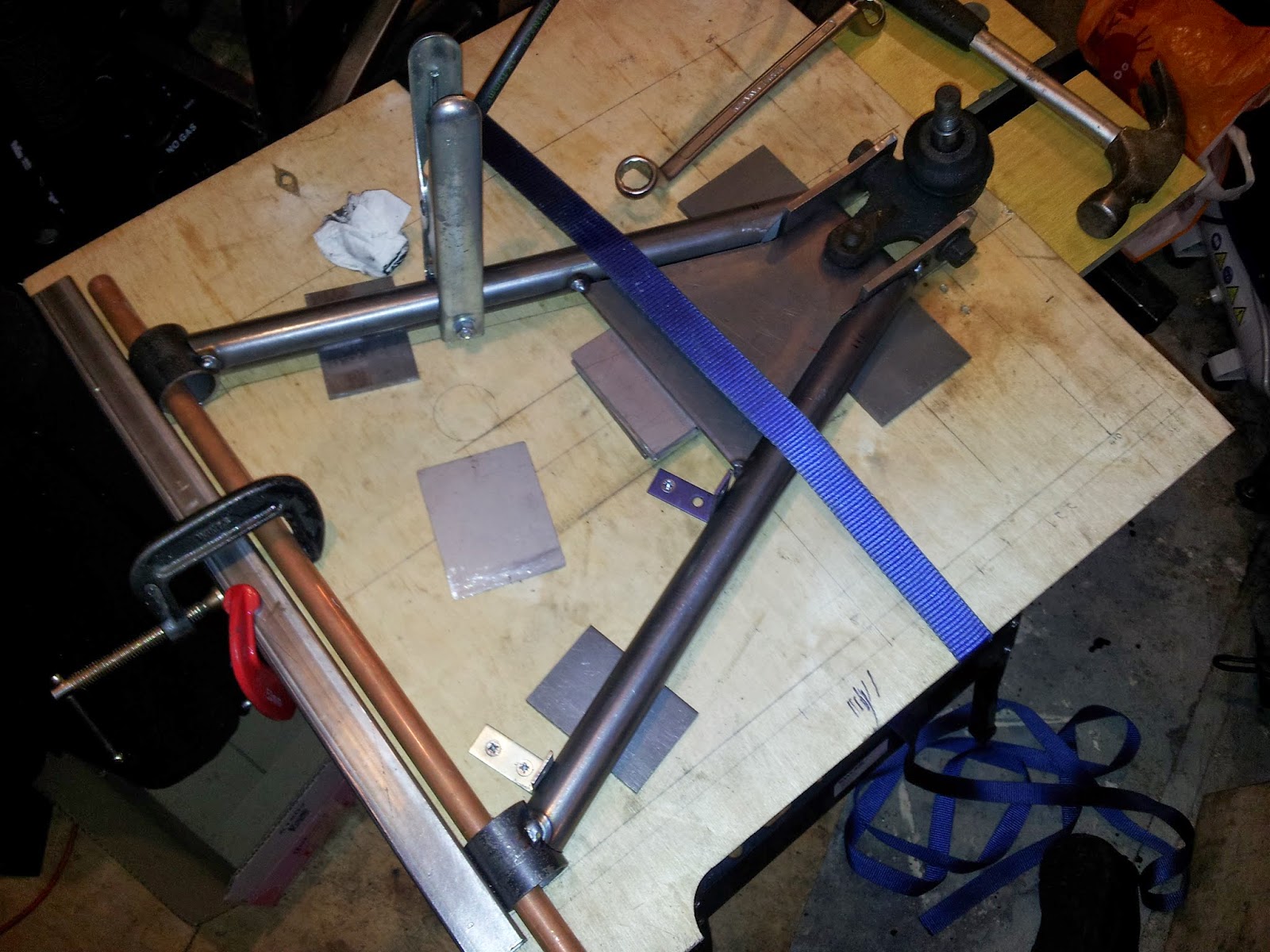

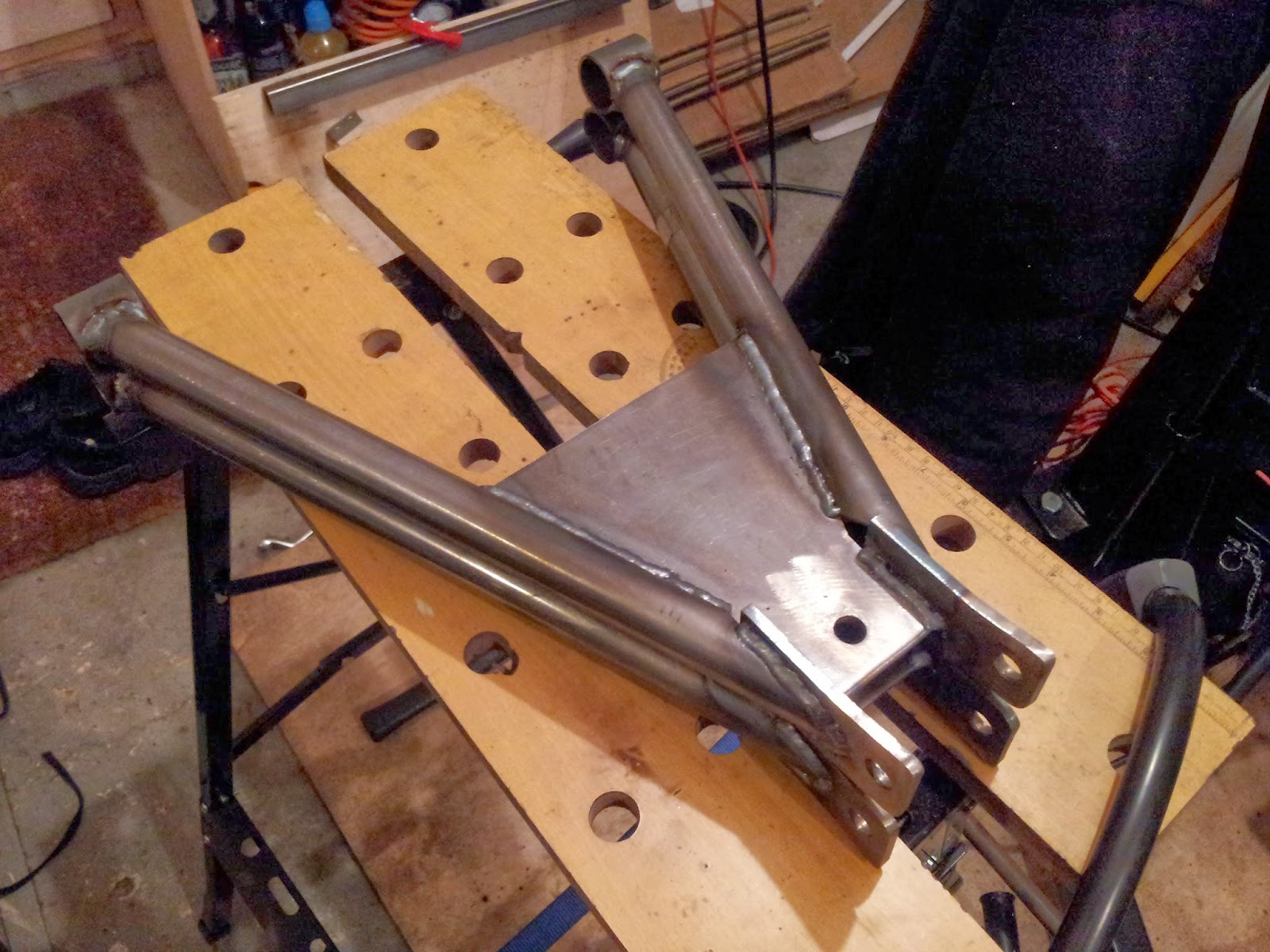

So ten minutes with a flap wheel on a grinder got them fitting perfectly. Straps and clamps aplenty ready for welding;

And a short time later I had two wishbones!

Putting them back to back showed that there was less than 1 millimetre difference between the bush tubes and the balljoint fixings, so I'm really happy.

I just have a couple of holes in the end of the tube to finish off, but I might pour some waxoyl in there first. It'll probably all get burnt away as I finish the weld, but at least things will stay rust proof.

The cut tubes left an interesting profile, which got me thinking about the next stage. I need to sleeve the threaded inserts for the top wishbones, and I was advised to cut the sleeve at an angle to maximise the weld length. As it so happens, the sleeve tube is the same tube I used here!! So;

The two on the left are bare offcuts, the two on the right are the inserts welded into place. With them fully welded as they are, the BMW balljoint still fits perfectly. Tomorrow I'll grind down those welds, and put the other two offcuts on top. Once they're welded on, I'll have a completely sleeved insert with good welds holding it tight. It's still only 50mm long (the original plans call for 60mm) but the threaded part of the balljoint is only 50mm long so I'm not worried.