One of the things that has bugged me with the donor parts has been the wheel bearings front and rear. They didn't feel bad and were never highlighted as an MOT issue on the donor car history, but it seemed really strange to not replace them. The reason I'd not done them yet was simply because I couldn't get them apart!

Reading many forums seemed to agree with my assessment, they're usually so meshed together that they should only be taken apart if absolutely required. And it's very likely that some breakages and replacement parts will be needed. There was also mention of 20 ton presses, scaffolding poles as breaker bars, and all sorts of other stuff.

But doing some further research I could see that replacement parts weren't particularly expensive. On the front the bearing and hub were a single unit, as they are on the rear of most cars. Coincidentally they are actually used on the Mazda Demio/121 of a similar era (1990-2005). So while searching for MX5 front bearings gave a lot of very expensive options, a search for Demio rear bearings got lots of cheaper ones! A pair of hubs/bearings were £46 delivered.

Next were the rears. The stub axles were not going to survive, I resigned myself to that. The nuts were also going to end up in fragments on the garage floor. Fortunately the stub axles contain the CV joint so they're intended to be a replaceable item. These are MX5 items only, but a pair cost £31. They also come with replacement nuts so that meant I could go to town on those without worrying.

The last item for the rears was the bearing itself. Apart from wanting to replace the bearing anyway (the whole point of this exercise) the design of the stub axle means that the bearing collapses when it's being removed. So it has to be replaced. Again, Mazda makde things really simple and had this wheel bearing used by many cars. £25 for a pair, no problem.

This meant a full set of replacement bearings and associated parts was £102 delivered to the doorstep. That's pretty much spot on in my opinion.

The stripdown was so much more effort though. The four hub nuts got the brunt of the angle grinder and powerfile, and did indeed end up as bits on the garage floor!

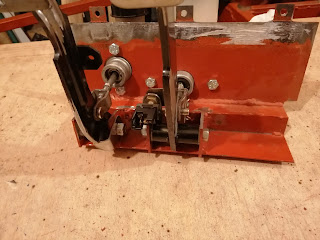

I have a decent hub puller from previous car maintenance, so with a bit of encouragement the fronts came apart quite easily. The new ones will go on, and then torqued up as required.

The rear took much more work to do the same task. In the end I got my impact gun on to the hub puller and just gave it everything I had. The vibrations of the impact gun, combined with the immense pressure that a hub puller can apply, managed to press the stub axle out of the hub. After removing the bearing internals that had just collapsed as expected, the outer race was then hammered out of the hub. Finally the last job was to detach the stub axle from the driveshaft, it was just a spring clip holding it in the same as any other driveshaft so a few thumps with the hammer sorted it.

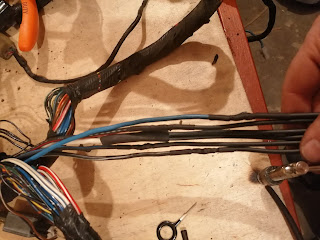

Once all the parts were cleaned up (CV joint grease is really horrible stuff!!) the parts can go back together again. At time of typing this update the bearings have been pressed into the uprights, and I've done some cleanup on the hubs ready to give them a lick of paint. They had been painted before but access issues meant it was a bit of a rubbish job.

So that's it for the bearings, everything is where it should be and it'll be ready to bolt back together in the final position. Another job ticked off the list. Well, it was a job added and then ticked off, but it needed to be done!

No pictures on this one, with the various bits of metal going all over the place and lots of hammering I thought my phone wouldn't last very long. In fact I was fairly accurate with my estimate, I had since found a bottle of beer with a severely dented cap, and I had a pencil torch that ended up in pieces and has been glued back together.