So there are a few alternatives. The first is probably the easiest, some right angle plastic trim along the corners. Lots of cars do it, although for some reason I can't find a picture of one when I need one! The main thing with this is that it's applied at the end, so this is basically a fallback strategy. It's not a bad strategy, just not what I'd put as the top priority.

The next option is some edge trim. This is applied to the aluminium then the panel is riveted as normal. There are two problems with this. One, the panels will no longer fit flush, and considering the tolerances I've been working to are pretty tight, I think I'll actually have trouble fitting the panels. The other problem is damage. No matter how careful I am with the car, the trims are going to get scuffed and damaged. If I have some trim that is fragile but riveted in place, it doesn't give me much scope for repair. And that's if I don't damage it on the way in, after all the rivets apply a fair amount of force and the plastic might deform. So this option is off the table.

The 'correct' option for this type of car is vinyl on foam. This would certainly solve any sharp edges, but to be honest I just don't want it. Carpet is similar, I could get it trimmed pretty decently but it's not what I want. I'm going for a 'raw' version of the Healey, very stripped down and ready for the (theoretical) track.

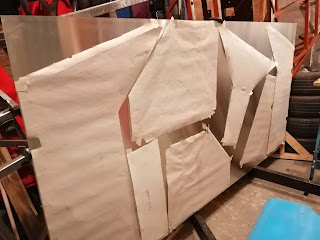

The last option is one that would give the best result but would be the hardest to do. Other cars with aluminium interiors rely on the curved surface of bent panels to provide the rounded edge. For example with the side panels the top of the aluminium is beaten over the top rail. This means that the radius doesn't need to be large in order to get rid of the sharp edge.

Based on this Youtube video;

I was wondering whether the same approach would work. Speaking to the author of the video though, he suggests that the cutter would just 'dig in' to the aluminium, and leave me with a mess. However, he did suggest a scraper approach might be better, so basically the same device but with a vertical blade.

The cutter itself will be a 90 degree, 2mm rounded edge. Using the tool steel I bought, this means I'll need a 4mm hole with a slot leading to it. The slot needs to be wider than the aluminium as I don't want the edges of the steel to touch the surface of the sheet. This will be fixed inside a wooden block similar to the above, with the wooden block having a 2mm slot to hold it in position. Hmm, maybe I should 3d print it...